Both instructors and airline pilots have started their careers flying some single-engine aircraft but —even though— you currently fly planes with a different technology, let’s not forget we can have friends or relatives that are starting in our field. For this reason, it is good to remind them one of the main problems in carburetor airplanes that, for so long, has raised concerns of North American and European authorities. This is the ice formation in the carburetor in weathers as warm as that of Florida (USA) or even in jungle areas during the summer.

Nowadays, several pilots of small planes still think the ice formation only occurs in temperate or cold climates. Indeed, if we talk about ice formation, we automatically think of snowfalls, mountains and scarves, but nothing could be further from the truth and statistics.

In the United States alone, carburetor icing has caused more than 250 accidents in the previous decade with an average of 2 fatal accidents per year (source: NTSB). On the other hand, the United Kingdom registers an annual average of 10 incidents of which 7 are accidents and many of them are related to conditions in which we would consider the ice formation as “unlikely.”

The ice formation in the induction system is basically due to 3 elements: Air temperature, environmental humidity and carburetor design.

Breaking down a myth: Air temperature and Environmental humidity

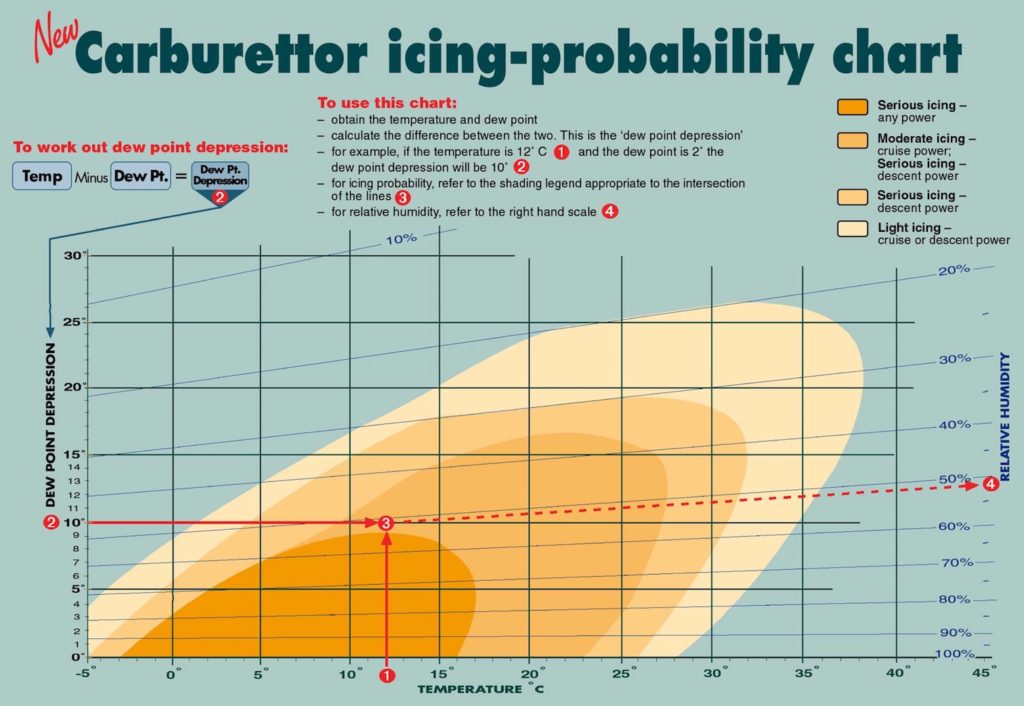

We have always read or been taught that ice formation in the carburetor can occur at temperatures up to 21 degrees Celsius, but that is false. Recent studies —and explained in the attached chart— show that carburetor icing can happen at temperatures as high as 38 degrees Celsius and with a relative humidity as low as 30%. This breaks down the myth that ice formation is impossible in hot environments.

In addition, no matter how hot the environment is, if the temperature and dew point are very close together, the odds increase.

High humidity areas should be consider when:

a) Visibility on the surface and at low flight levels is poor, especially early in the morning and in the afternoon before it gets dark, in particular near large sources of water (lakes, rivers, sea.)

b) The land is wet and the wind is light.

c) Below the cloud base or between cloud layers.

d) During rainfall, especially if they are continuous, regardless of the size of drops.

e) In mists or fogs because they are composed of small droplets of water, therefore humidity is 100%.

f) In clear air where clouds or fog have recently dissipated.

The Carburetor Design:

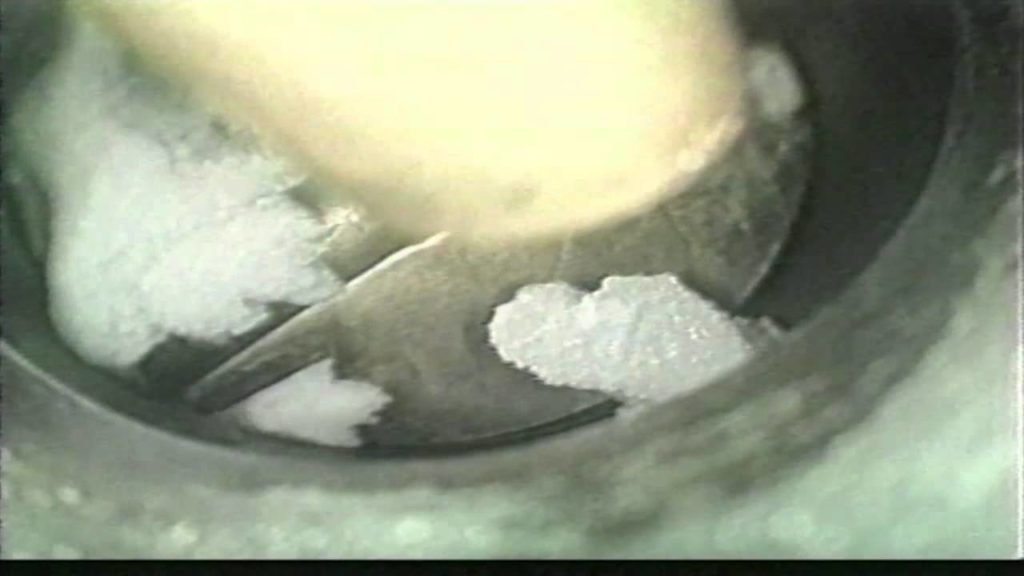

The shape of the carburetor both in the throttle valve (butterfly) and in the venturi throat favors the development of a thermodynamic effect called The Joule-Thomson effect. This explains the temperature drops of real gases when they are forced to pass through a valve (for ideal gases is what we know as Pressure x Volume / Temperature.) When passing through a smaller area, the air is forced to speed up (law of continuity). If its speed increases, the pressure drops, and if the pressure drops, the temperature also drops (it can fall up to 30 degrees of temperature.)

Said problem worsens as we close the throttle valve (like in descents) since the flow area of the fuel/air mixture is shorter, speeding up fluids much more and increasing the chances of ice formation, as explained above.

Prevention:

Now that we know the ice formation is not exclusively due to low environmental temperatures, we must be alert —in any weather during our flights— to reductions in engine RPM’s that make us suspect (after checking our parameters) that ice is forming in the carburetor with the aim of activating immediately the Carburetor Heat.

In most small airplanes, landing checklists indicate the application of the Carburetor Heat as “As Require.” However, considering the abovementioned studies regarding the high probability of ice formation when we are descending, its use could be mandatory during all the time of the descent. This would be a good safety measure by operations departments, especially in areas with high humidity. Aircrews should be reminded this action leads to a reduction in engine power, which is reflected in a drop of the RPM´s, mainly for 3 reasons:

1) Decrease in the density of air entering the combustion chamber due to heating caused by the use of the Carburetor Heat.

2) Thermodynamic inefficiency, since when the fuel temperature rises, it loses power that should have been used for combustion. In other words, it is a somewhat “weakened” fuel.

3) Incomplete fuel combustion, taking into consideration that the mixture is very rich, it does not burn completely so during combustion some of the fuel is wasted and —unfortunately— not all the power is used.

As we can see, the ice in the carburetor does not form exclusively in cold environments but can occur at any stage of the flight, especially during descents. In addition, the carb heat should not only be used to melt but also to prevent, and although you no longer fly single-engine aircrafts, it is important to share this information with those who are starting in this career, since it could be the difference between a safe landing and one more number in accident statistics.

The attached image shows how to estimate the probability of ice formation by intersecting the dew point depression (Depression = current temperature minus dew point) on the left side and the current temperature at the bottom of the chart.

Click in the following link if you want to print it:

http://www.ycem.com.au/b2/CarbIceV1.JPG

Dithel Bless

http://www.ycem.com.au/b2/CarbIceV1.JPG

Dithel Bless